Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Below are selected projects that showcase our expertise in design, engineering, and problem-solving across different industries and applications.

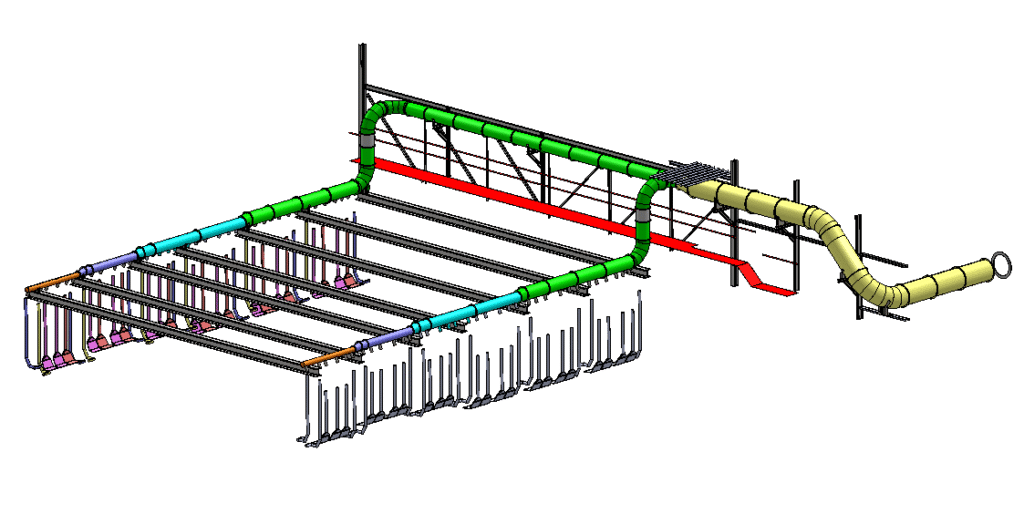

3D Scanning & Piping System Design

For this project, we combined advanced 3D scanning technology with mechanical design to deliver an accurate and efficient piping solution. The process began with a full 3D laser scan of the facility, capturing every structural detail with millimeter precision. Using this data, we built a detailed digital model of the environment, which served as the foundation for designing the new piping system.

The Challenge: The client needed a new piping system to be installed in an existing facility. Traditional methods of measurement and layout risked inaccuracies, clashes with existing structures, and costly delays.

Our Approach: We began by performing a full 3D laser scan of the facility, capturing precise details of walls, structures, and existing systems. Using this point cloud data, we created a highly accurate digital model of the environment. From there, we designed the piping system directly within the scanned model, ensuring every component would fit seamlessly into place.

The Results

- Improved Accuracy: Millimeter-level precision reduced design errors and installation conflicts.

- Faster Design Cycle: Working from scan data accelerated the design process.

- Cost Savings: Reduced rework and minimized downtime during installation.

- Optimized Layout: A piping system that integrated smoothly with the facility’s infrastructure.

By combining 3D scanning with advanced mechanical design, we delivered a solution that was both efficient and reliable—helping the client save time, reduce risk, and achieve a smoother project execution.

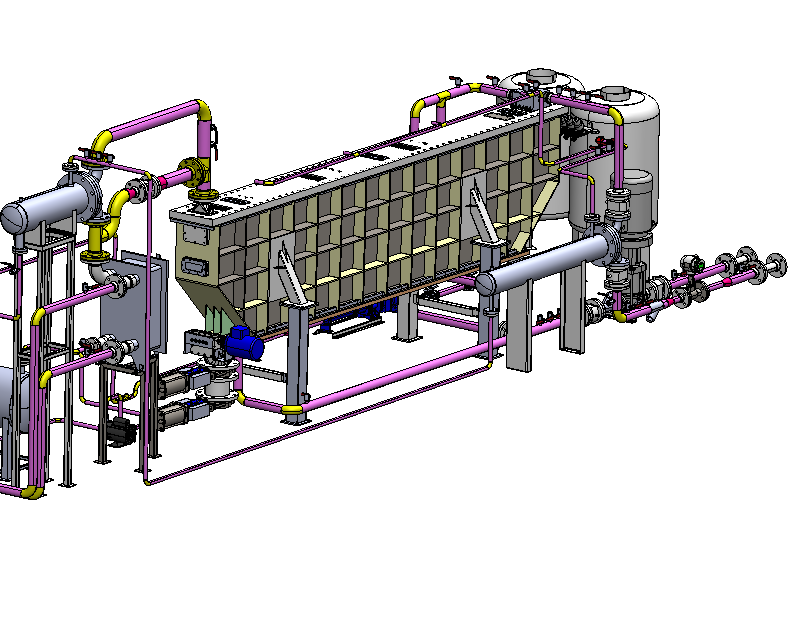

Thermodynamic Machine for Water Evaporation

The Challenge: The client required an efficient solution to evaporate water as part of their industrial process. Conventional systems consumed excessive energy and lacked the precision needed for reliable operation, leading to high operational costs and inefficiencies.

Our Approach: We designed a custom thermodynamic machine tailored to the client’s process requirements. The system was developed to maximize heat transfer efficiency while maintaining control over temperature and evaporation rates. Using engineering calculations and simulation, we optimized the design to balance performance, durability, and energy efficiency.

The Results

- Energy Efficiency: Reduced energy consumption compared to conventional systems.

- Process Reliability: Stable and controlled evaporation, improving overall process consistency.

- Custom Design: A machine tailored to the client’s unique operating environment and needs.

- Cost Savings: Lower operational expenses thanks to optimized thermal performance.

By applying thermal calculations and mechanical design expertise, we delivered a machine that not only met the client’s requirements but also enhanced efficiency and long-term sustainability of their process.

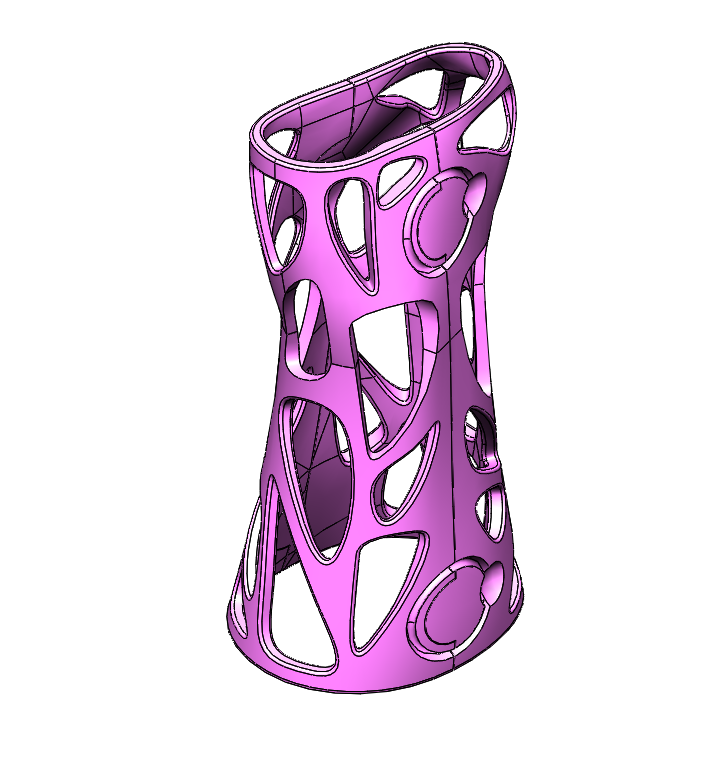

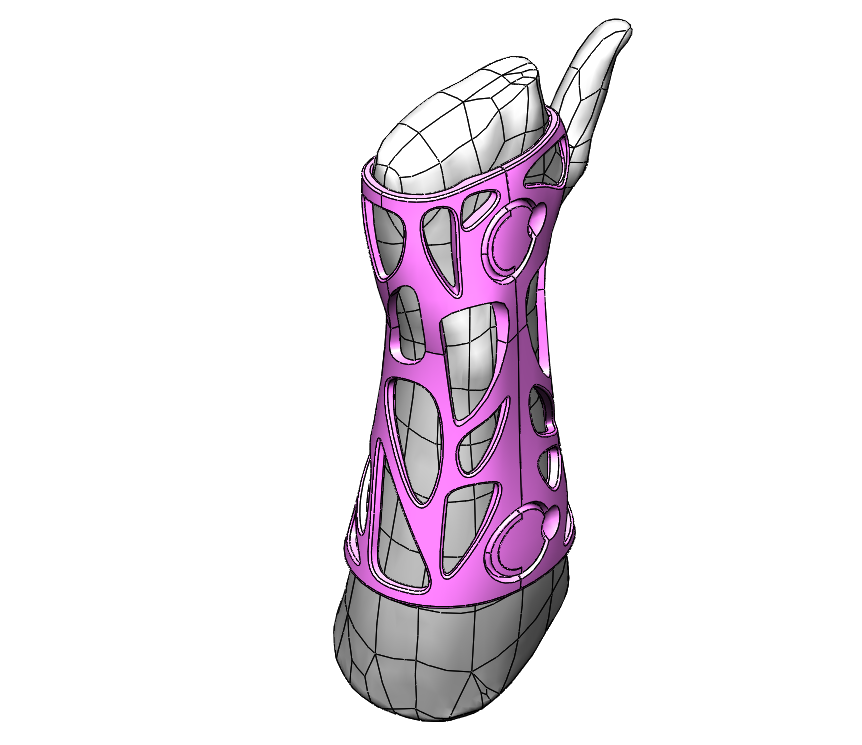

3D Printed Prosthetic Covers & Splints

We applied 3D modeling and additive manufacturing to design and produce customized prosthetic covers and splints. Each design was tailored to the patient’s anatomy and specific needs, ensuring proper fit, functionality, and comfort. Using 3D printing allowed us to quickly prototype, refine, and produce final parts with optimized geometry and minimal material waste.

Our Approach: Using 3D modeling and additive manufacturing, we created customized prosthetic covers and splints tailored to individual anatomy and needs. The process allowed for quick prototyping, refinement, and final production with optimized geometry.

The Results

- Fully customized designs for patient comfort and usability.

- Lightweight and durable components.

- Faster turnaround through rapid prototyping.

- Cost-effective compared to traditional methods.

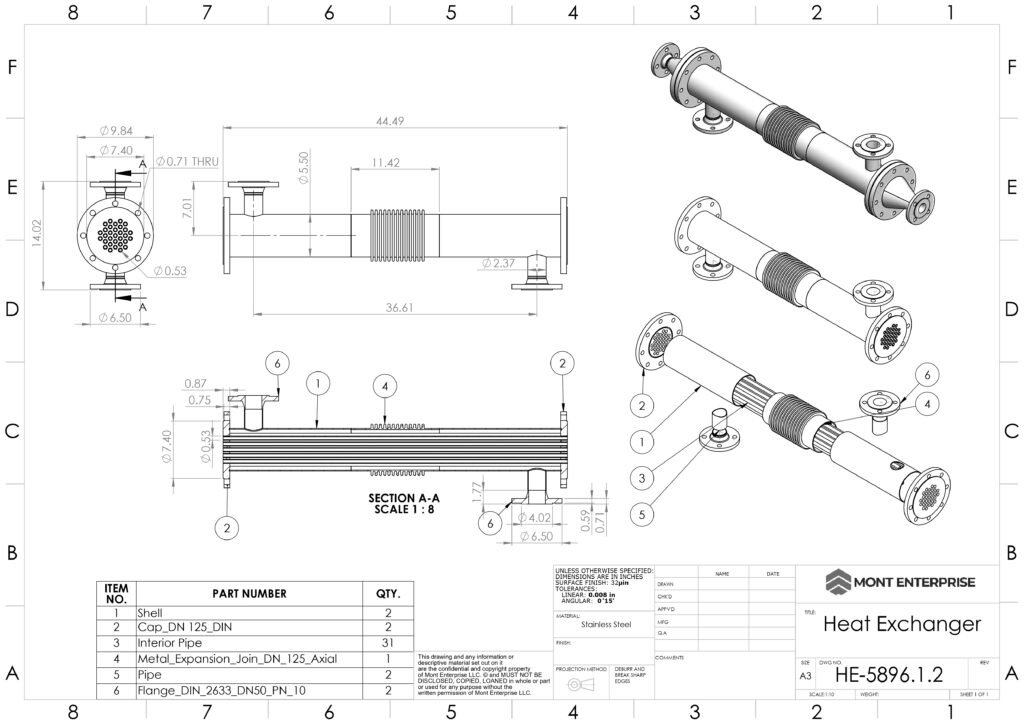

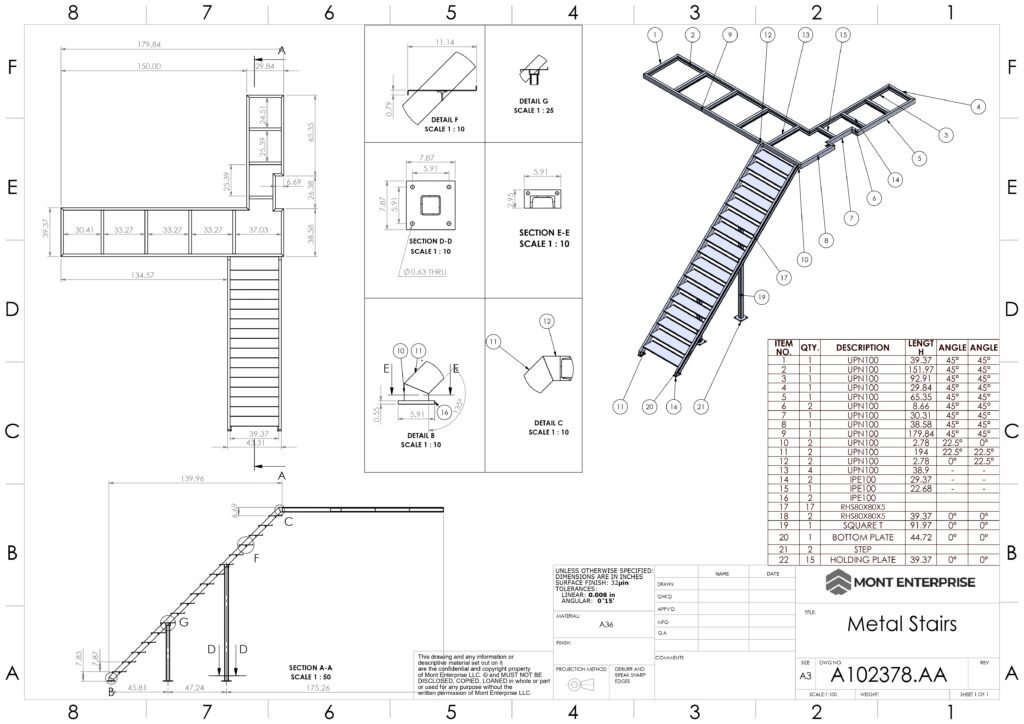

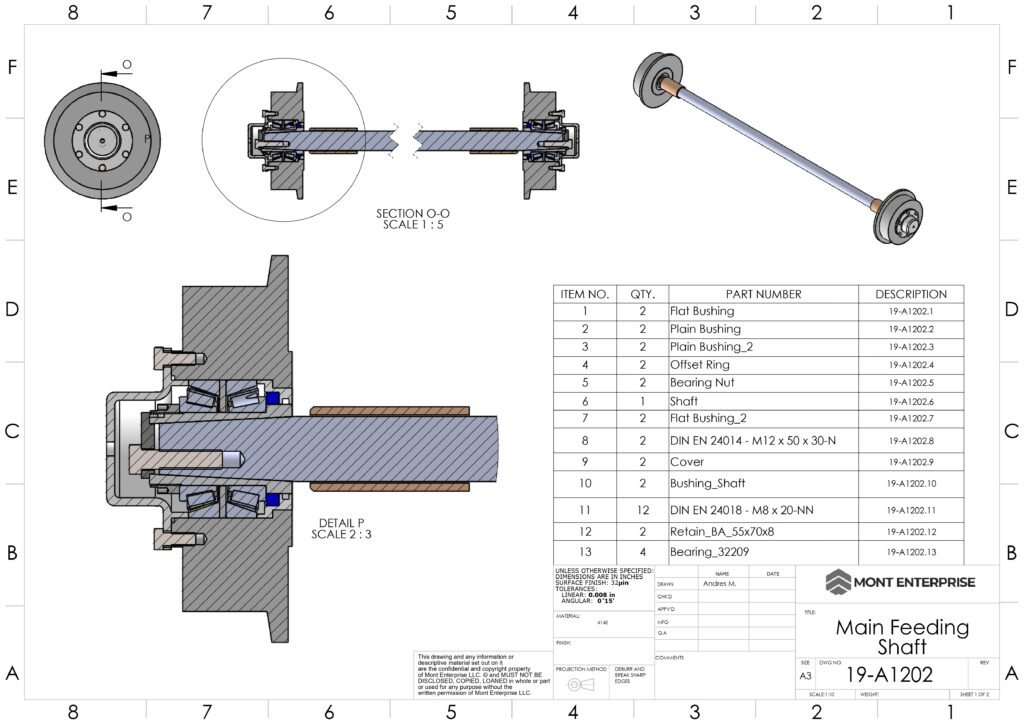

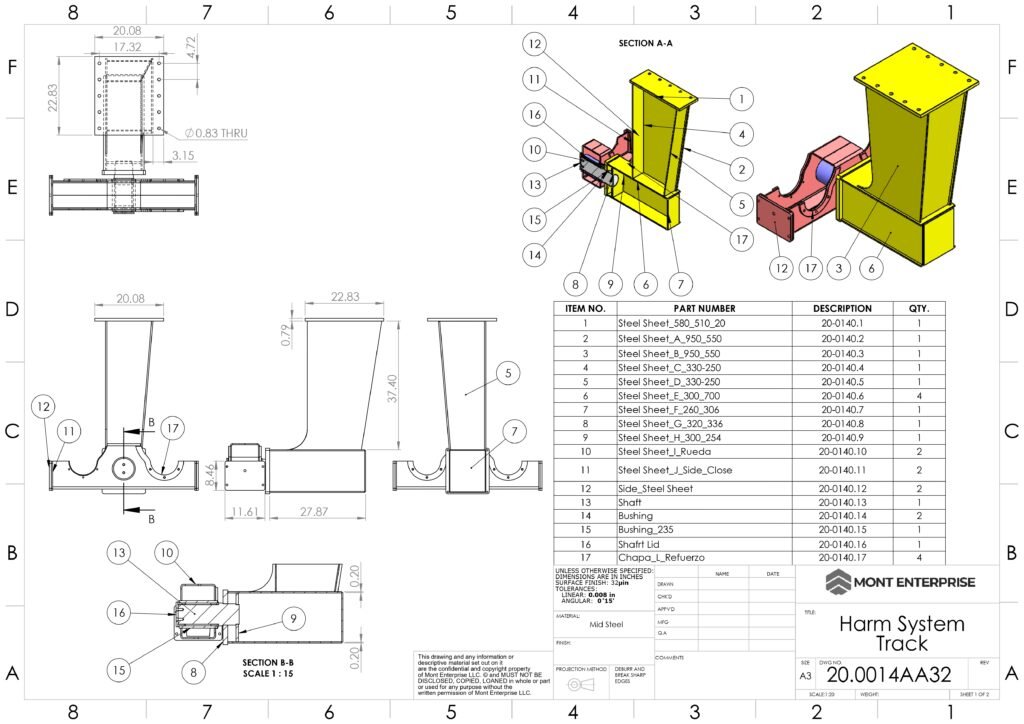

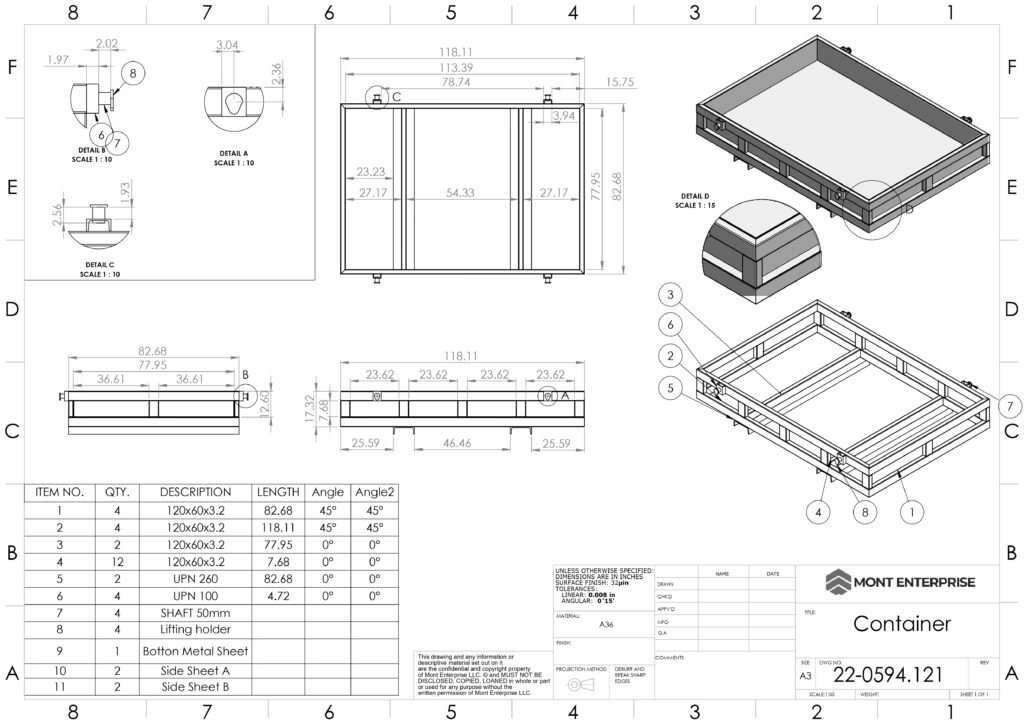

Drafting Services for Manufacturing & Construction

The Challenge: Clients often face delays and miscommunication when technical drawings lack clarity or do not meet industry standards. Inaccurate documentation can result in costly mistakes during fabrication and assembly.

Our Approach: We provided professional drafting services, creating precise 2D and 3D technical drawings tailored for manufacturing, construction, and assembly teams. By adhering to engineering standards and ensuring clear annotations, we delivered documentation that acted as a reliable bridge between design and production.

The Results

- Accuracy: Reduced errors in fabrication and assembly.

- Clarity: Easy-to-read drawings improved communication across teams.

- Compliance: Industry-standard documentation ensured compatibility with suppliers and fabricators.

- Efficiency: Faster production with fewer revisions and delays.

Through detailed and reliable drafting, we enabled clients to move from concept to production with confidence, minimizing risks and saving both time and cost.

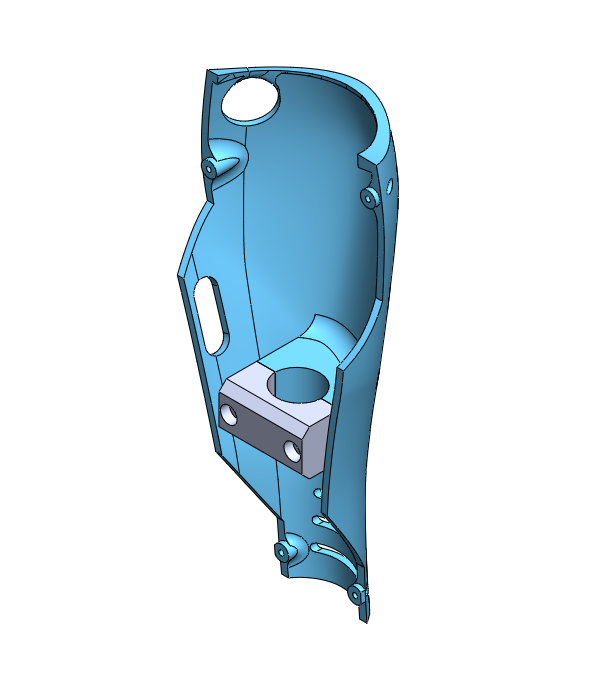

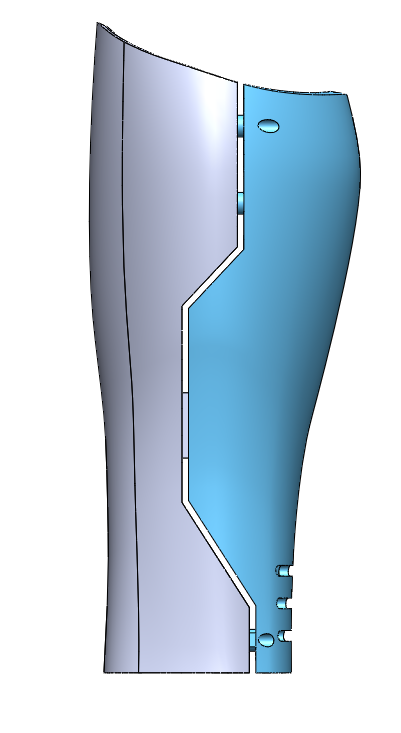

Standing Wheelchair Design & Construction

The Challenge: Conventional wheelchairs often limit mobility to a seated position, restricting independence and contributing to long-term health issues such as poor circulation, muscle atrophy, and reduced social interaction. The client needed a solution that could combine the practicality of a standard wheelchair with the benefits of standing mobility.

Our Approach: We designed and built a mechanical wheelchair with standing functionality, allowing the user to transition safely from a seated to a standing position. The system integrated ergonomic design, durable materials, and precise mechanical components to ensure both stability and ease of use. Special attention was given to safety features, weight distribution, and user comfort.

The Results

- Improved Mobility: Enabled users to move independently in both seated and standing positions.

- Health Benefits: Supported circulation, posture, and muscle engagement.

- Enhanced Independence: Allowed users to interact at eye level and access environments otherwise out of reach.

- Custom Engineering: A robust and user-centered solution tailored to the client’s needs.

This project highlights how engineering and human-centered design can work together to improve quality of life and empower individuals with greater independence.